The hotel is a 150-room property located in Geneva, New York, and has been heated and cooled by a geothermal system since its installation in 1997. Each guest room is served by a dedicated forced-air geothermal heat pump, while a centralized water-to-water geothermal system supports the building’s domestic hot water needs. The system is connected to a large vertical loopfield, estimated to include between 150 and 200 boreholes, installed beneath the hotel’s parking lot. Forward-thinking for its time, the system was engineered to deliver efficient, all-electric heating and cooling, making it a sophisticated example of early commercial geothermal design still operating today.

How a Hotel’s Misunderstood Geothermal System Nearly Cost Them $1 Million

A geothermal system is an ecosystem of interconnected parts: An underground loopfield, fusion-welded piping, pumps, controls, and fluid chemistry. When designed, operated, and maintained correctly, these systems can perform reliably for decades.

But that only holds true when:

- The system is designed by geothermal professionals

- Maintenance is performed by technicians who understand geothermal physics

- Troubleshooting is based on how the loopfield and equipment interact

Calling someone unfamiliar with geothermal to diagnose a problem is risky—and expensive.

It’s like calling your doctor to diagnose your dog’s illness.

They may be brilliant at what they do, but it’s not their specialty.

The Situation: A Forward-Thinking System, Decades Later

The hotel’s geothermal system was installed in 1997, making it both impressive and rare. At the time, it was a forward-thinking design:

- Approximately 150 guest rooms, each with its own forced-air geothermal heat pump

- A shared domestic hot water system supported by water-to-water geothermal units

- Indoor pool supported by a dedicated water-to-water geothermal system

- A vertical loopfield installed beneath the parking lot

- An estimated 150–200 boreholes, though original project drawings were lost or illegible

Unfortunately, while the original design was solid, the long-term operation and maintenance were not.

The Emergency Call: “The System Is Down”

We received a frantic call:

- The geothermal system was offline

- The loopfield was leaking

- Multiple HVAC companies had already looked at it

- Limited records and no system as-built drawings

- The proposed solution by a local HVAC company? Total system replacement with boilers and cooling towers — at a cost exceeding $1 million and negatively impacting the property’s carbon footprint.

Why such an extreme recommendation?

Because the companies called before us were traditional HVAC contractors with zero geothermal expertise. They didn’t understand the system’s components, how the loopfield worked, or how to diagnose the real issues.

The hotel owner was stuck, until they called a geothermal specialist: ACES Energy.

Why Geothermal Systems Must Be Designed and Maintained by Professionals

Within the first hour, our geothermal team diagnosed the core problems using the information available on site and the invaluable knowledge of a maintenance team member who had been there for nine years.

Here’s what we discovered:

- The system was not operating at peak efficiency

- The loopfield was filled with 100% glycol to prevent freezing

- Unoccupied rooms were set to cooling to “add” heat to the loop during the winter time

- Key components were misunderstood or misused

- Short-term “fixes” replaced long-term solutions

We identified leaks at transition points in the vertical boreholes:

- Improper fittings (and lack of) used during original installation

- Poor pipe fusion techniques

- No 90-degree fitting at the top of the well head to manage pipe bends

The result? Broken HDPE connections and loopfield fluid forcing its way through the parking lot asphalt to the surface.

Our fix:

- Excavated sections of the parking lot

- Cut out the broken pipe and installed proper 90-degree fused fittings

- Repaired a failed butt fusion with a correct socket fusion

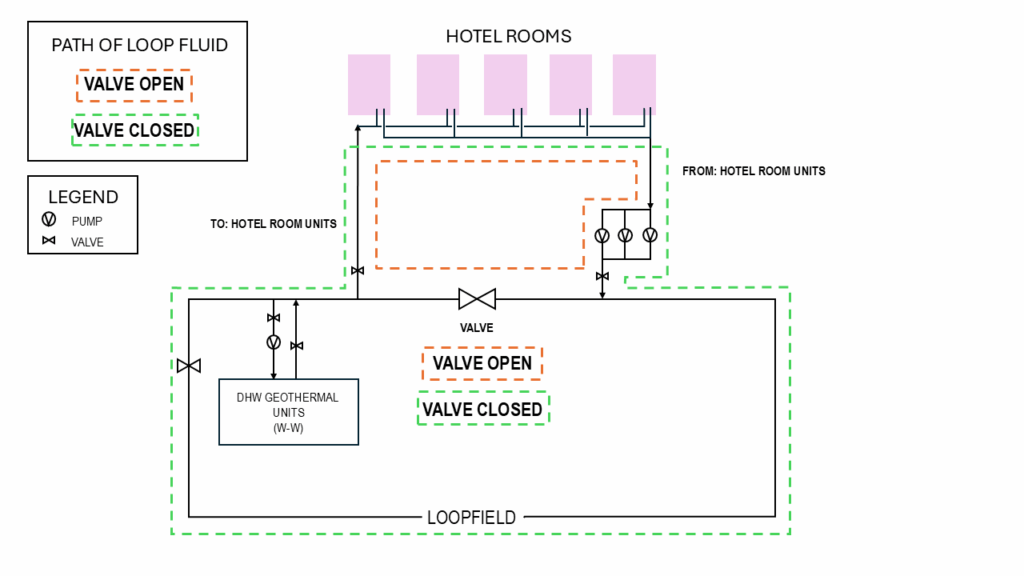

Another Problem: The Loopfield Was Being Bypassed

The most damaging issue wasn’t the leak, it was how the system had been operated.

A valve installed to be used for geothermal service only was open (supposed to be closed), resulting in a significantly restricted flow to the loopfield. As a result:

- Loopfield water circulated through hotel equipment

- A small amount of the loopfield fluid actually returned to the loopfield (heat exchanger)

- Heat exchange with the earth was minimal

In simple terms:

The system wasn’t using the ground to heat or cool itself.

The Consequences

- Loop temperatures dropped below 32°F

- Freezing became a constant risk

- Maintenance staff filled the system with 100% glycol to prevent freeze-ups and added heat tape to important valves

What they didn’t realize was that simply closing one valve would have forced water through the loopfield, allowing the ground to do its job.

When we corrected the valve position, loop temperatures jumped from 32°F to 54°F almost immediately.

That’s geothermal physics working as intended.

Years of Workarounds Instead of Solutions

Because the loopfield hadn’t been fully utilized for years, the system struggled to maintain adequate heat capacity in winter.

To compensate, maintenance staff resorted to creative, but inefficient, solutions:

- Placing unoccupied guest rooms in cooling mode

- Extracting heat from the rooms

- Dumping that heat into the loopfield to “recharge” it

While clever, this approach was a sign of a deeper issue:

The system was being managed without a full understanding of how it was designed to operate.

Why Professional Geothermal Expertise Matters

This project could have gone very differently.

Without geothermal specialists, the hotel was on the verge of:

- Abandoning an efficient geothermal system

- Installing fossil-fuel boilers

- Spending over $1 million unnecessarily

Instead, with the right expertise:

- The loopfield was repaired

- Proper flow was restored

- Loop temperatures stabilized

- The system was brought back online

All without replacing the entire system, and with about 2 days work.

Flush & Fill Complete: Restoring System Performance

The geothermal system flush and fill has now been successfully completed, marking a major milestone in restoring proper system operation. To make this possible, our team connected over 100 feet of hose from our geothermal flush trailer to the building’s mechanical space, allowing direct access to the loopfield for high-volume circulation and filtration.

Over the course of the process, approximately 36,000 gallons of water were used to thoroughly flush the loopfield. This intensive circulation removed significant amounts of sediment and dirt, which had accumulated over time and were restricting system performance.

The operation was supported by three ACES geothermal experts (AJ, James and Ryan!), ensuring the flushing was performed efficiently, safely, and in accordance with best practices.

What This Accomplishes

Completing the flush and fill allows us to:

- Remove contaminants that had entered the loopfield

- Restore proper fluid quality and flow characteristics

- Protect newly repaired piping and connected equipment

- Re-establish reliable heat transfer and system efficiency

With the loopfield cleaned, refilled, and operating as intended—and with proper ongoing professional maintenance—this geothermal system is now positioned to deliver many more years of dependable, high-performance operation.

The result:

- Over 99% of the projected replacement cost avoided

- A fully functional geothermal system returned to service

- Avoided switching to a boiler, which would have increased energy costs, carbon emissions, and long-term maintenance needs

Why geothermal beats a boiler:

- Lower operating costs: Geothermal uses the stable ground temperature to heat and cool, reducing energy use compared to boilers.

- Environmentally friendly: All-electric operation produces fewer carbon emissions than fossil-fuel boilers.

- Long-lasting: Properly maintained systems can last decades, often outlasting multiple boiler replacements.

- Dual functionality: Provides both heating and cooling from a single system, unlike boilers.

This case shows why geothermal systems need specialized expertise. Misunderstood, they look like failures. Understood, they deliver efficiency, sustainability, and long-term savings.

COMMENTS